Effective inventory planning is a complex and demanding task, even for major food companies.

This is because a single mistake in inventory planning or management can cause a huge direct impact on your business. Management team leads regularly ask themselves a crucial question: Do we have enough inventory to meet the current demand for orders?

Inventory Planning Challenges

Everyday food companies deal with thousands of products, with various demands and inventory levels across multiple locations.

While large businesses have dedicated teams, such as operations managers and production managers, efficiently handling inventory can still be a challenge. This is because the teams need to ensure that stock levels match the sales demand around the clock.

Additionally, during inventory planning, they need to guarantee that their inventory can last long enough while counting future demands and orders.

Modeling Food inventory

So how do you simplify or “ease” the process?

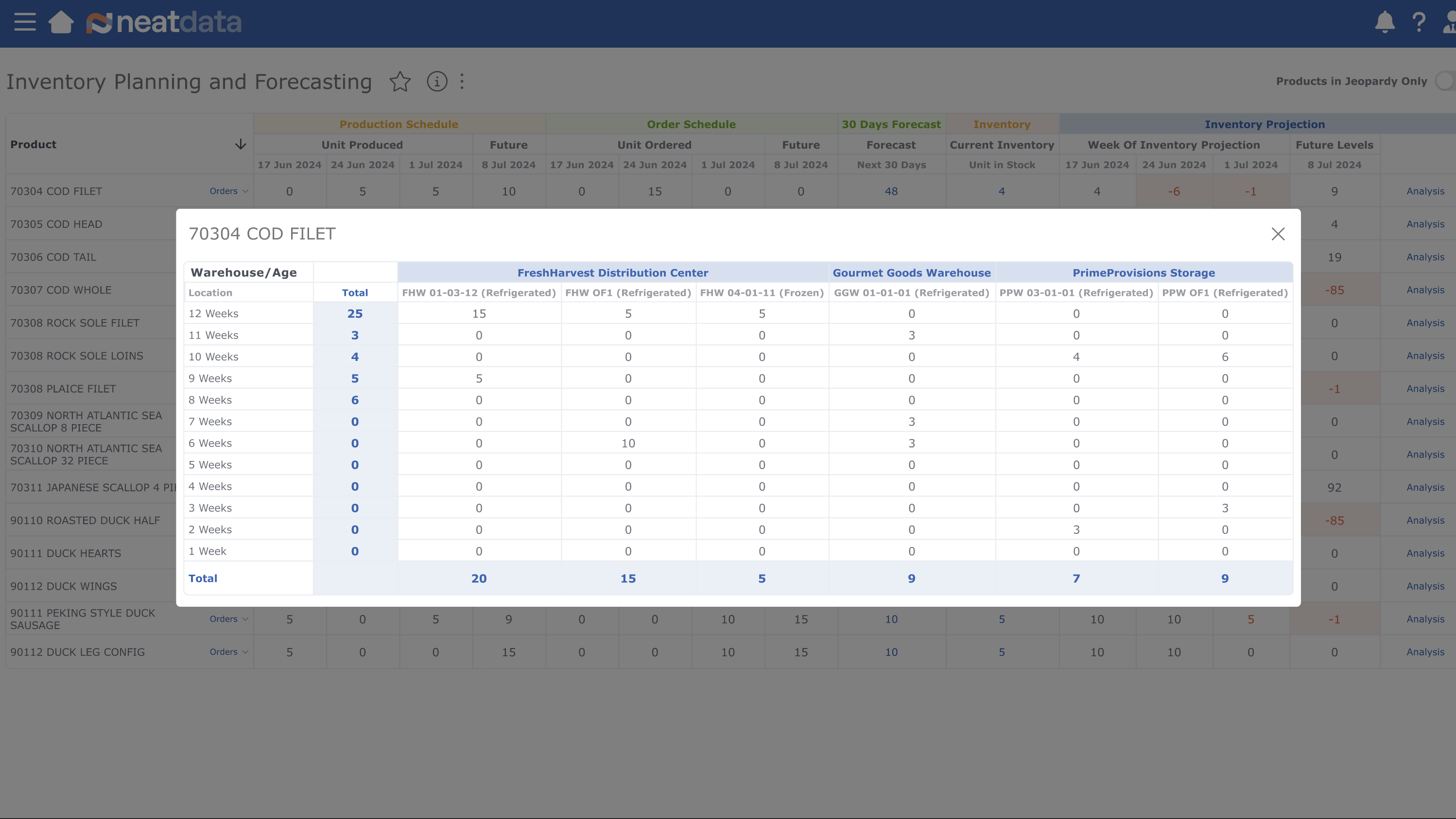

The first step in finding a solution for inventory planning is efficiently modeling all the information of your inventory. This includes several essential components, including the products themselves, the warehouse locations where they are stored, and the specific lots they belong to.

Another important factor to account for is the various units of measure that further add to the complexity of modeling the inventory. Some products are tracked in weight while others are individual items.

Importing this data from ERP software makes the challenge even more difficult. Careful attention is required to ensure that all and only the relevant information is integrated into the inventory model.

Forecasting Orders with Machine Learning

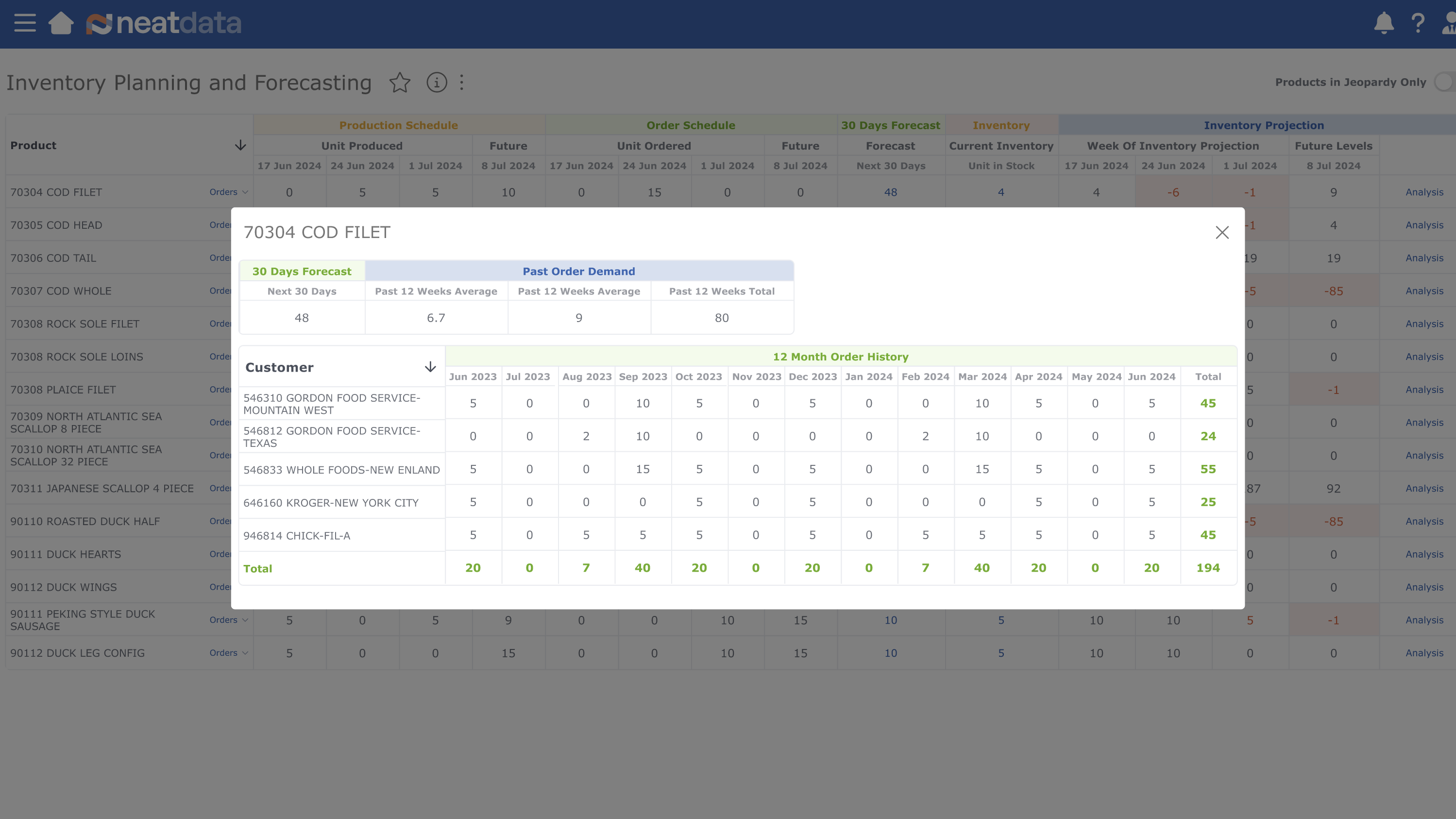

One crucial aspect of food inventory planning or modelling is the details of current order demand for forecasting inventory requirement.

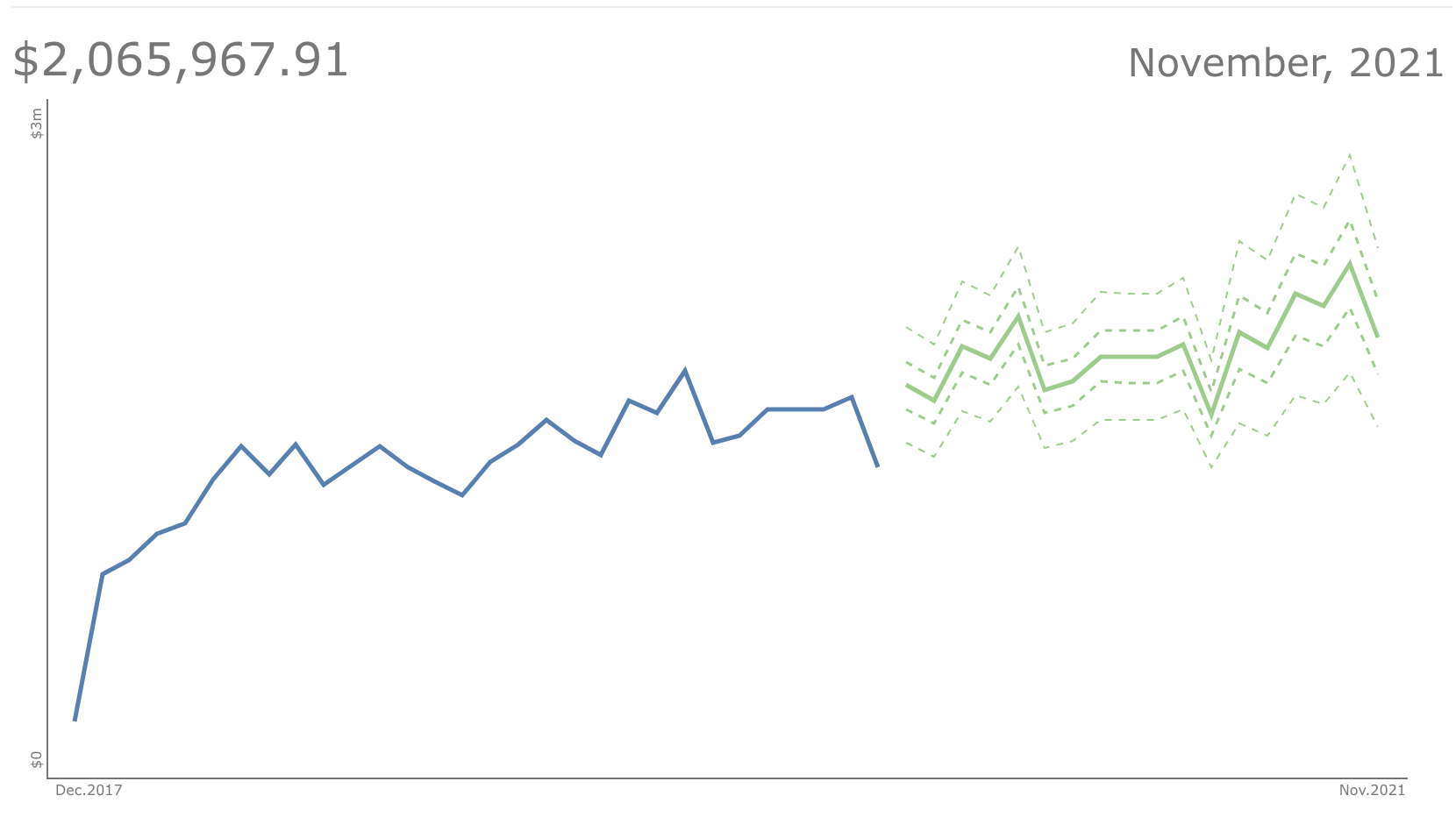

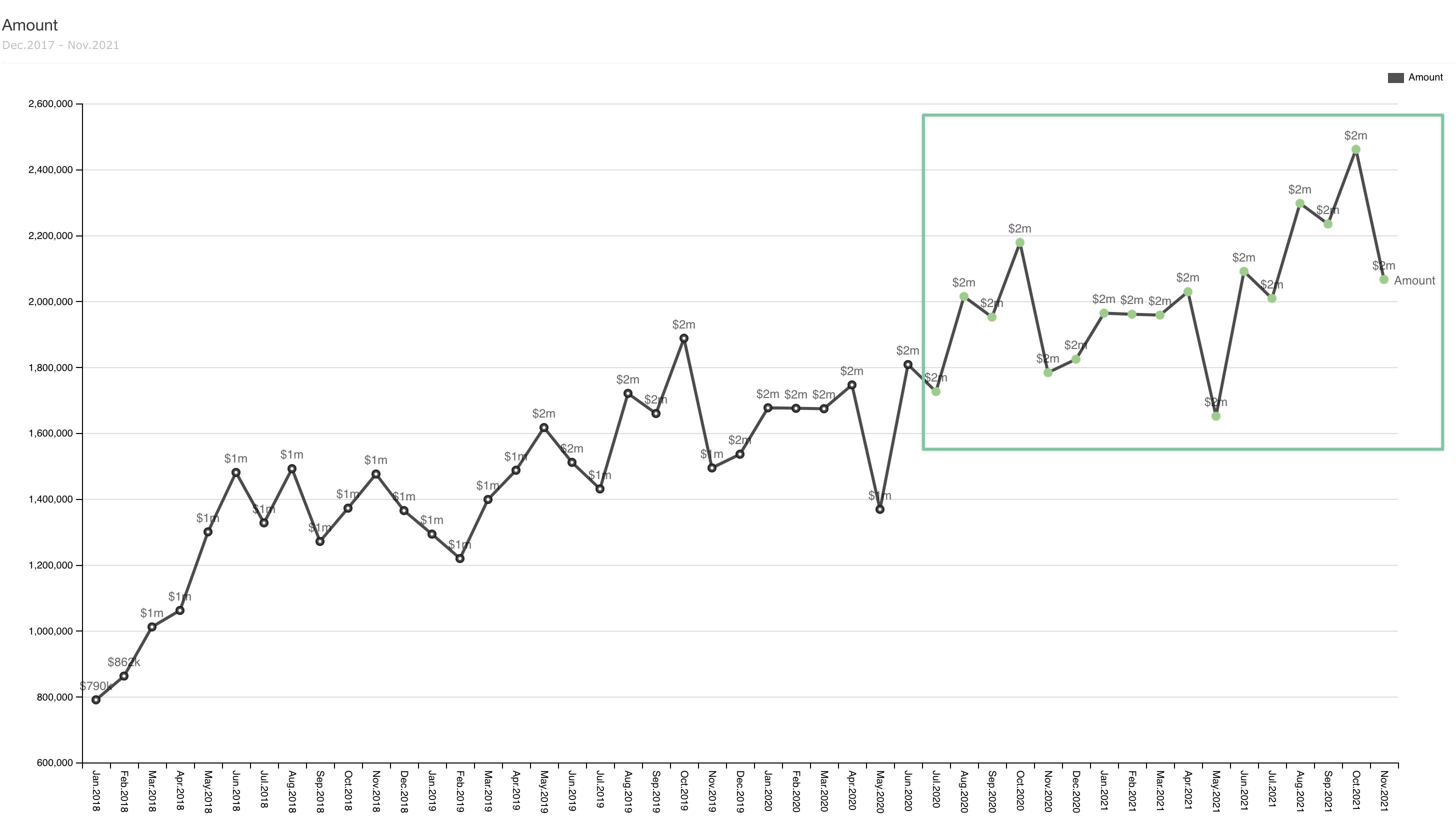

Additionally, you would also need to understand the order history for all your products for more reliable estimation. This is where machine learning comes in.

Machine learning or AI is able to recognize and identify prior patterns to project what the future demand will look like for each of those products. It reads the order history to better estimate sales demands, based on seasons, holidays, trends, etc.

Your daily dashboard

Once you have modeled your inventory history, and estimated the future demand, it’s time to plan out your inventory.

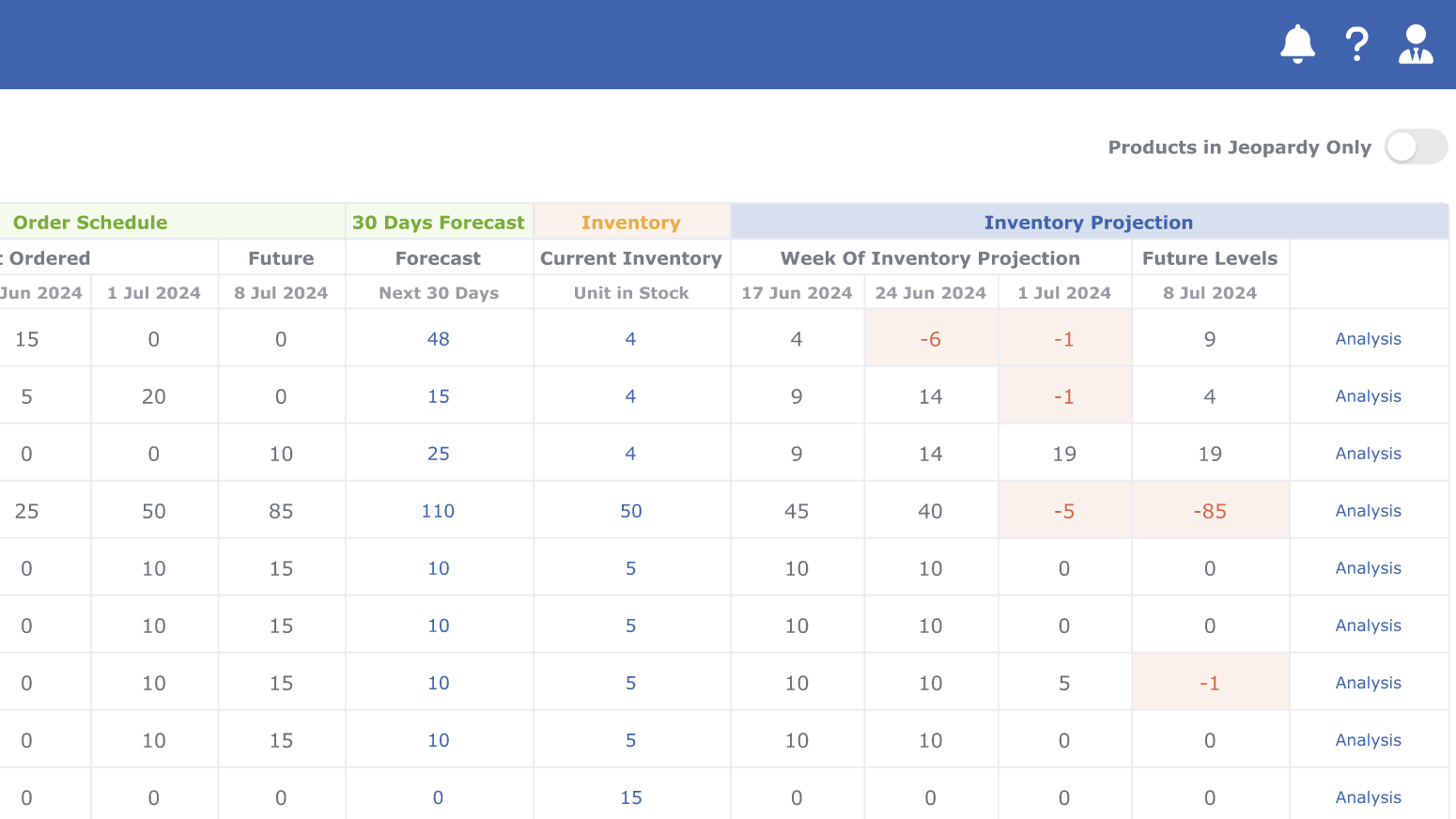

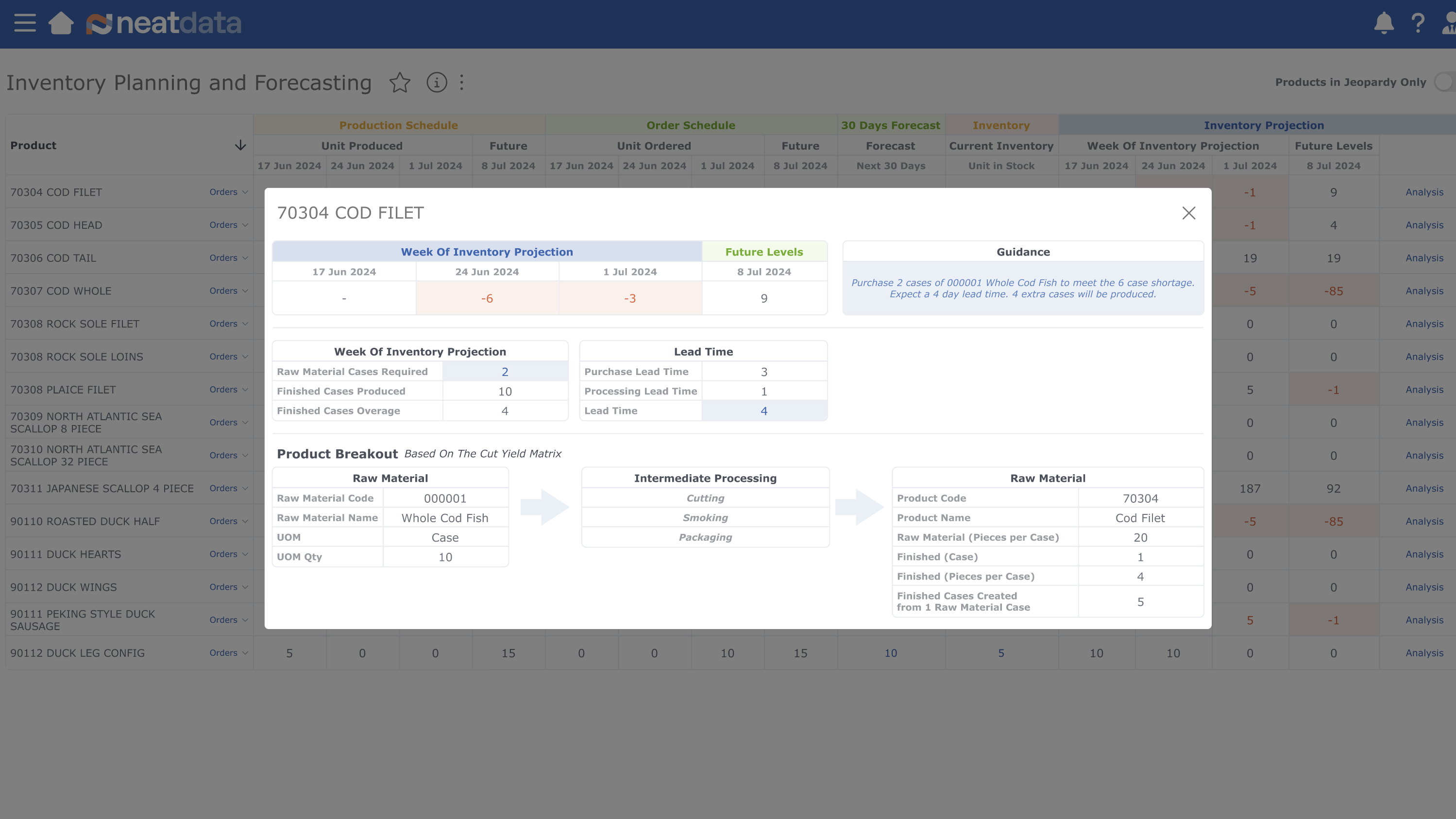

The daily dashboard of Neat Data’s new inventory planning module helps you with just that. It works on four main parts:

- Production schedule: This part of the dashboard outlines the timeline and volume of products that are planned for production.

- Order demand and forecast: This section displays the current order demand for your products, as well as a forecast of future.

- Current inventory levels: As the name suggests, this is where you monitor how much of each product you have at any give time.

- Products in jeopardy: This section is mainly to handle any emergencies, as it highlights products that are at risk for not meeting the current or future sales demands.

Conclusion

Managing food inventory, especially due to high volume of data can be tricky. This challenges only alleviates because of the nature of the food business.

However, it is not impossible. With the help of the Neat Data’s inventory planning module, things get a little more easy to manage. The module gathers pieces of information of your business and provides you detailed platform that acts as a one-stop solution for your planning.

Remember, with the right tool and strategy in place, effective food inventory planning becomes not just achievable but a key driver of business success.